Blog

Measurement Methods and Precautions for the Internal Resistance of LiFePO4 Batteries

Internal resistance is an important parameter of LiFePO4 batteries, reflecting the performance and health status of the battery. Accurate measurement of the internal resistance of LiFePO4 batteries is crucial for battery design, production, quality control, as well as performance evaluation and fault diagnosis during use.

Definition and Significance of LiFePO4 Battery Internal Resistance

Definition of Internal Resistance

The internal resistance of a LiFePO4 battery refers to the resistance encountered by current as it flows through the internal components of the battery. It consists of two parts: ohmic resistance and polarization resistance. Ohmic resistance is primarily composed of the resistance of electrode materials, electrolytes, and separators, and is independent of the current. Polarization resistance arises from the polarization phenomenon during the electrochemical reaction and depends on factors such as current and temperature.

Significance of Internal Resistance

The magnitude of the internal resistance directly affects the battery's output power, charging efficiency, discharge performance, and service life. Batteries with lower internal resistance can provide higher output current and power, have lower energy loss during charging, and experience smaller voltage drops during discharge, resulting in better performance and a longer lifespan.

Methods for Measuring LiFePO4 Battery Internal Resistance

DC Internal Resistance Measurement Methods

- 1. Short-circuit Current Method

- Principle: Short-circuit the battery, measure the maximum current and the voltage across the battery terminals at the moment of short-circuit, and calculate the internal resistance using Ohm's law.

- Advantages: Simple operation, fast measurement.

- Disadvantages: Large short-circuit current may damage the battery, and the results are highly influenced by contact resistance.

- 2. Pulse Current Method

- Principle: Apply a short-time high-current pulse to the battery, measure the voltage changes before and after the pulse, and calculate the internal resistance using Ohm's law.

- Advantages: Less damage to the battery, more accurate measurement.

- Disadvantages: Requires high-precision measuring equipment and complex control circuits.

AC Internal Resistance Measurement Methods

- 1. AC Injection Method

- Principle: Inject a small-amplitude AC current signal into the battery, measure the AC voltage response across the battery terminals, and calculate the internal resistance by finding the ratio of voltage to current.

- Advantages: High measurement accuracy, minimal impact on the battery.

- Disadvantages: Complex measurement equipment, higher cost.

- 2. Electrochemical Impedance Spectroscopy (EIS) Method

- Principle: Apply a series of small-amplitude AC signals at different frequencies within the battery's operating frequency range, measure the battery's impedance response, and analyze the impedance spectrum to determine internal resistance.

- Advantages: Provides rich internal battery information, such as electrode reaction kinetics and charge transfer resistance.

- Disadvantages: Long measurement time, complex data analysis.

Comparison and Selection of Measurement Methods

Method Comparison

The DC internal resistance measurement method is suitable for quickly assessing the internal resistance of a battery, but the results may be affected by polarization. The AC internal resistance measurement method offers higher measurement accuracy but requires complex equipment and higher costs.

Selection Criteria

Choose an appropriate measurement method based on factors such as measurement purpose, accuracy requirements, cost, and measurement conditions. On production lines, fast DC internal resistance measurement methods are typically used for preliminary screening, while higher-precision AC internal resistance methods are used in research and quality control.

Precautions for Measuring LiFePO4 Battery Internal Resistance

Measurement Environment

- 1. Temperature Control:

- Keep the measurement environment temperature stable, as temperature has a significant impact on the internal resistance of LiFePO4 batteries. Measurements should generally be conducted within the specified temperature range, and the results should be temperature-corrected.

- 2. Humidity Control:

- Avoid high humidity to prevent affecting the performance of the measurement equipment and the battery.

Calibration of Measurement Equipment

- 1. Regular Calibration:

- Measurement equipment should be regularly calibrated to ensure the accuracy of the results.

- 2. Precision Selection:

- Choose measurement equipment with appropriate precision based on the measurement requirements.

Battery Status

- 1. Charging Status:

- Ensure the battery's charging status (fully charged, partially charged, or discharged) is clear before measurement, as internal resistance may vary depending on the state.

- 2. Resting Time:

- The battery should rest for a period before measurement to allow the internal components to stabilize.

Contact Resistance

- 1. Optimize Connections:

- Ensure good contact between the measurement clamps and the battery terminals to reduce the impact of contact resistance on measurement results.

- 2. Clean Contact Surfaces:

- Keep the battery terminals and clamps clean, removing dirt and oxidation.

Measurement Frequency and Time

- 1. AC Measurement Frequency:

- Choose the appropriate AC measurement frequency based on the battery's characteristics and the measurement purpose.

- 2. Measurement Time:

- Control the measurement time to avoid performance changes in the battery due to prolonged measurements.

Data Analysis and Processing

- 1. Repeated Measurements:

- Perform multiple measurements and take the average value to improve the reliability of the results.

- 2. Outlier Processing:

- Analyze and process outliers in the measurement data to determine whether they are measurement errors.

Conclusion

Accurately measuring the internal resistance of LiFePO4 batteries is crucial for assessing the battery's health, optimizing design, and improving performance. The internal resistance directly affects the battery's power output, charging efficiency, discharge performance, and service life. The choice of an appropriate measurement method should be based on specific needs, such as the measurement purpose, accuracy requirements, and cost considerations. Whether using a fast DC measurement method or a high-precision AC method, it is essential to pay close attention to factors such as temperature control, equipment calibration, battery status, and contact resistance during the measurement process to ensure the accuracy and reliability of the results. Repeated measurements and data analysis can further enhance the credibility of the results, ensuring precise evaluation of battery performance.

- Next:CATL starts solid-state battery sample validation, competing with Toyota, LG, and BYD for leadership in solid-state battery technology.

- Previous:How to Tell if Your Lithium Battery is Safe? 7 Warning Signs You Should Know

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

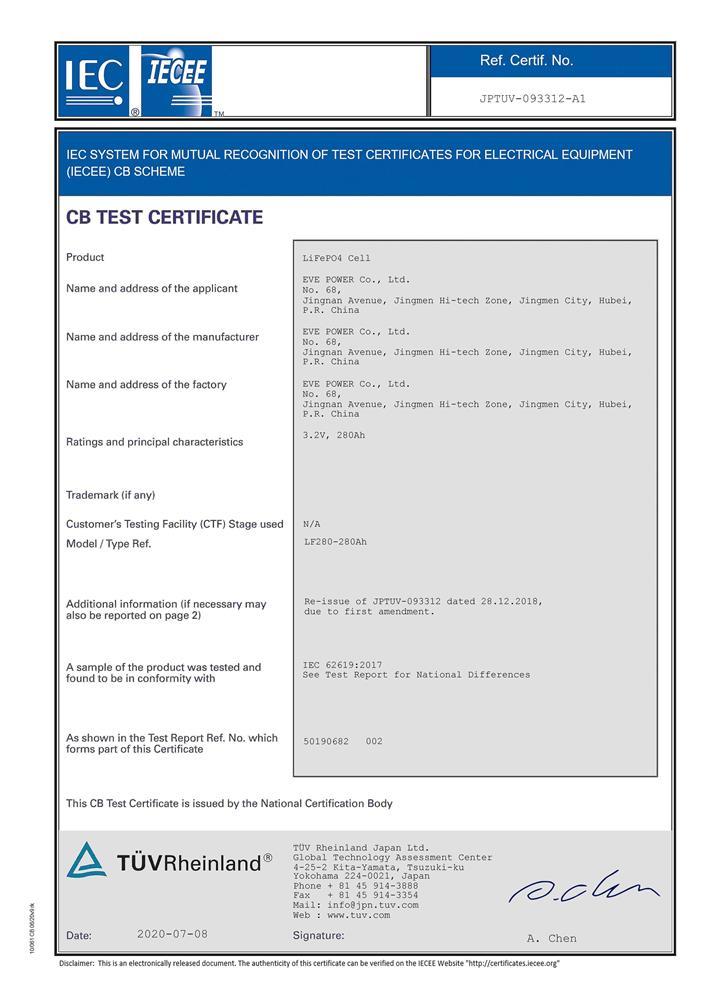

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia