Blog

CATL starts solid-state battery sample validation, competing with Toyota, LG, and BYD for leadership in solid-state battery technology.

We have exclusively learned that CATL has increased its R&D investment in solid-state batteries this year, expanding its R&D team to over 1,000 people.

CATL is currently focusing on the sulfide route and has recently entered the 20Ah sample production stage. According to an informed source, CATL's current plan can achieve an energy density of 500 Wh/kg for ternary lithium batteries, an improvement of over 40% compared to existing batteries, although the charging speed and cycle life have not yet met expectations.

Solid-state battery sample production typically starts with 1Ah and gradually increases the single battery capacity. The task during the 1Ah sample stage is to test the performance of the battery materials; at the 10Ah sample stage, the focus shifts to testing the performance of individual cells; the 20Ah sample stage indicates that the battery design is initially determined and enters the stage of exploring production technology.

In April this year, CATL's Chief Scientist, Wu Kai, mentioned at an international battery technology exchange conference that CATL had built a 10Ah solid-state battery performance validation platform and made progress in the anode and cathode materials, processes, and manufacturing equipment for solid-state batteries.

Now, CATL has entered the 20Ah sample production stage—currently, the capacity of soft-pack batteries used in electric vehicles is 20Ah. If the safety and performance issues can be solved at this stage, the remaining tasks are mainly related to manufacturing engineering, which can be effectively advanced by increasing manpower and experimental iterations.

CATL's Chairman, Zeng Yuqun, classified the solid-state battery R&D progress into nine levels. He stated at the Power Battery Conference in September this year that CATL is currently at level 4, with the goal of reaching levels 7-8 by 2027 and achieving small-scale production of solid-state batteries.

CATL's timeline is similar to that of Toyota, LG Energy, Samsung SDI, and others, slightly ahead of BYD. However, Zeng Yuqun boldly claimed in September this year that CATL's research is "a big step ahead" compared to its competitors, stating in English, "Second to none."

Zeng Yuqun's confidence may come from unprecedented investment levels.

Solid-state batteries are viewed by the industry as the ultimate form of lithium batteries, and both academia and the industry consider it the ideal battery form. However, for the past 30 years, only Toyota has continuously invested in R&D for solid-state batteries, and its progress has been slow.

For the first time, a company like CATL has invested massive resources in R&D for solid-state batteries. "1,000 people, with an average cost of 1 million per person, means 1 billion in salary every year. Most solid-state battery companies could not even afford to build laboratories with budgets of a few hundred million." said an industry insider.

From Following to Betting, From No Goal to Mass Production by 2027

Energy density is the most important performance indicator for batteries, as it represents the efficiency of battery usage. For the past 30 years, most battery companies have worked on improving the energy density of batteries, packing more energy into batteries of the same size and weight.

From Sony and Panasonic to CATL, battery companies have increased the energy density of lithium batteries from 120Wh/kg to the current 320Wh/kg. This improvement in energy density has enabled lithium batteries to enter more fields, creating more business opportunities and driving the energy transition.

Unlike the semiconductor industry's Moore's Law, battery performance does not double at regular intervals. But the world has never needed as many lithium batteries as it does now—global lithium battery production has increased tenfold in the past five years, but energy density has only grown by less than 30%.

In the foreseeable future, the potential for improvement in liquid lithium batteries used in electric vehicles and smartphones is limited: the theoretical energy density limit for liquid ternary lithium batteries is 350Wh/kg. This number can only extend the battery life of a smartphone by half an hour or allow an electric vehicle to travel an extra 50 kilometers on a single charge.

Along the liquid lithium battery route, it will never be possible to fly an electric passenger plane—the founder of Tesla, Elon Musk, once calculated that battery energy density must exceed 450Wh/kg before electric passenger planes become a reality.

Solid-state batteries have become the industry-recognized future form of lithium batteries.

The main components of a battery are the electrolyte and the anode and cathode, with lithium ions moving between the anode and cathode to charge and discharge, achieving energy storage and functionality.

In a solid-state battery, the liquid electrolyte (usually lithium hexafluorophosphate) used in current lithium batteries is replaced with a solid-state electrolyte. Solid-state electrolytes are more stable and safer, allowing for the use of higher-energy-density but more chemically reactive lithium metal as the anode (current anode materials are graphite) and higher-nickel ternary materials as the cathode, which can double the energy density limit of lithium batteries to over 700Wh/kg.

All lithium battery companies claim to be "researching" solid-state batteries, but before this year, most major battery companies only invested a handful of engineers to keep track of cutting-edge developments. The main reason for this approach is that current liquid lithium batteries still have room for improvement. Researching within the existing technological framework has more definite returns and a higher return on investment; furthermore, major battery companies in the industry believe that even if startup companies break through the technology first, they can quickly catch up by imitating.

CATL was also following this approach a few years ago.

According to our information, CATL's research into solid-state batteries began as early as 2016. At that time, CATL invited Liang Chengdu, who had worked for 10 years at Oak Ridge National Laboratory in the United States (a leading material chemistry laboratory founded in 1943 and involved in the Manhattan Project), to join CATL as Co-President of the R&D system and directly lead CATL's sulfide solid-state battery research project team.

However, a person close to CATL said that at that time, Liang Chengdu had fewer than 100 people working on solid-state battery R&D, and CATL's position was to "understand the latest developments in the laboratories and companies to help upper management make technical decisions." Until the end of 2022, CATL did not significantly increase its investment in solid-state battery R&D.

CATL's top management has previously been cautious about solid-state batteries.

Wu Kai, the Chief Scientist of CATL, said in mid-2022, "If Toyota says they can mass-produce solid-state batteries today, I would be skeptical. Currently, no company in the industry has the ability to mass-produce solid-state batteries. As for whether we can achieve mass production by 2027, it is difficult for me to make an accurate prediction as a technologist."

But in March of this year, Wu Kai shared CATL's solid-state battery R&D progress at a rare battery industry technology forum. Half a year later, Zeng Yuqun disclosed the timeline for "small-scale production of solid-state batteries in 2027."

Toyota, which started researching solid-state batteries the earliest, has repeatedly postponed its solid-state battery timeline since 2018. Last year, Toyota claimed it would mass-produce solid-state batteries in 2027. Many domestic startups have confused semi-solid-state batteries with solid-state batteries, forcing the industry to add the word "full" to indicate the solid-state batteries as originally envisioned.

Compared to them, CATL's timeline is considered more reliable and realistic in the industry.

By early this year, CATL began increasing its investment in solid-state batteries. It is understood that in the first quarter of this year, CATL introduced dozens of technical experts from solid-state battery startups and institutes such as the Chinese Academy of Sciences.

In March of this year, Zeng Yuqun also stated in an interview that he personally checks on the progress of the solid-state battery R&D team every month, keeping track of all technical developments. One of the engineers from the team said that Zeng Yuqun encouraged the team by saying, "If something good happens, don't look for me; if something bad happens, come to me, and I'll help you solve it."

While CATL has increased its investment in solid-state batteries, the Ministry of Industry and Information Technology (MIIT) has also provided R&D subsidies to six companies, including CATL, BYD, and Geely.

It is understood that the MIIT has provided over 6 billion yuan in R&D subsidies for the solid-state battery industry, though some funds will only be available once the enterprises make progress in their R&D projects. The MIIT's goal is to achieve small-scale production of solid-state batteries by 2027.

An industry insider said that after conducting research, the MIIT believes that solid-state batteries are theoretically feasible, and the only issue is the time required for production.

Reinventing Every Step in R&D

So, what's the most important difference between solid-state batteries and liquid batteries? One important factor is the manufacturing cost.

The R&D of solid-state batteries requires rethinking every aspect of the battery process.

One source from CATL said, "Currently, the most expensive part of a battery is the separator, the polymer separator used in current liquid lithium batteries, which costs less than 1 yuan per square meter. But the separator in solid-state batteries is much more expensive, and at present, there is no supplier with the ability to mass-produce this component."

Solid-state battery manufacturing is also very demanding in terms of temperature and humidity, and more material tests need to be carried out during the R&D process. In addition, testing and validation must be done on each component, and the process parameters must be developed.

Unlike liquid batteries, solid-state batteries are not easily replicated and require companies to solve material compatibility and manufacturing process issues. By increasing R&D investment, CATL has greatly reduced the cost pressure of R&D and production.

This is why CATL has grown its team to over 1,000 people. The main challenge for the R&D team at present is manufacturing process innovation, where dozens of engineers are dedicated to researching manufacturing processes and materials to ensure that solid-state batteries can enter the mass production stage.

Currently, the performance of CATL's solid-state battery prototypes is still far from mature and requires further development. However, once they overcome the challenges of manufacturing processes and other technical problems, CATL will be able to mass-produce solid-state batteries by 2027, bringing innovation to the industry.

- Next:Exploring the Functions, Applications, and Future Development of Battery Management System (BMS)

- Previous:How to Tell if Your Lithium Battery is Safe? 7 Warning Signs You Should Know

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

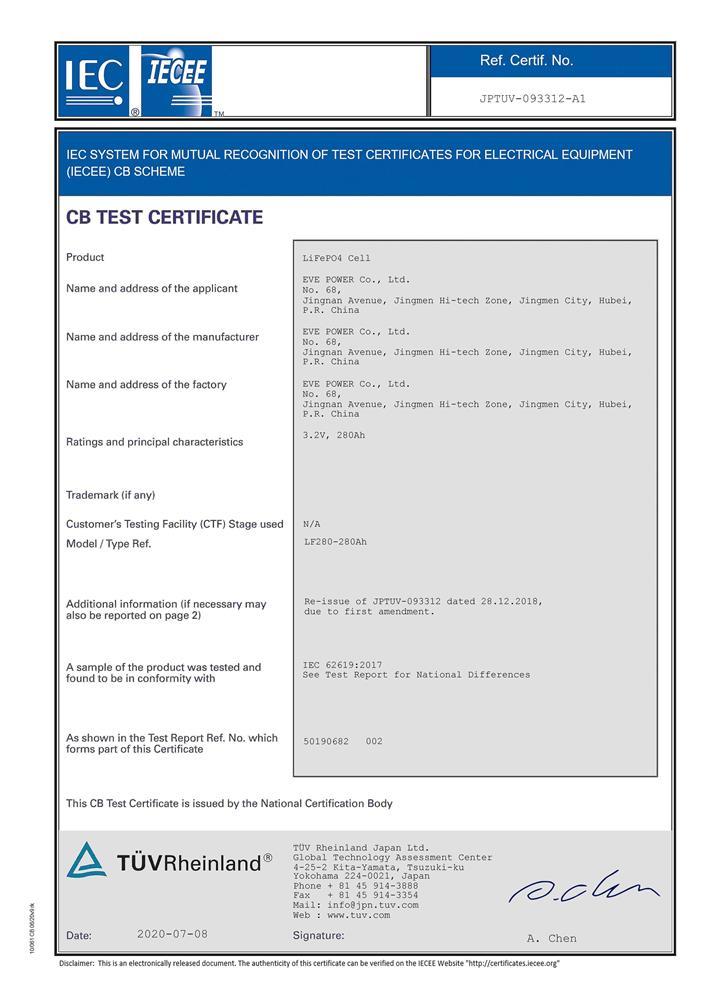

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia