News

General Motors Announces Adoption of LiFePO4 Battery Technology, Expected to Significantly Reduce Electric Vehicle Costs

At a recent investor event, General Motors (GM) Vice President of Battery Engineering and former Tesla executive Kurt Kelty announced a significant decision: GM will adopt lifepo4 battery technology to drastically reduce the cost of electric vehicles (EVs). According to Kelty, this move could lower the cost of an EV by up to $6,000, marking a major step forward in GM's efforts to promote the widespread adoption of EVs.

Currently, GM primarily uses nickel-cobalt-manganese (NCM) batteries on its Ultium platform, a common battery type in the EV industry known for its high performance and long life. However, NCM batteries are relatively expensive compared to lifepo4 batteries, which limits the market competitiveness of EVs to some extent.

lifepo4 batteries differ from NCM batteries in several key areas. In terms of cost, lifepo4 batteries have lower raw material costs and more stable production processes, making them overall cheaper than NCM batteries. According to Kelty, GM plans to reduce its battery costs to an average of $60 per kilowatt-hour (kWh) between 2023 and 2024, and expects to lower this further by $30 per kWh by 2025 through the use of lifepo4 batteries.

In terms of performance, while lifepo4 batteries have relatively lower energy density, they offer better thermal stability and higher safety. Additionally, lifepo4 batteries have a longer cycle life and can operate across a wider temperature range, giving them an advantage in certain applications. Kelty revealed that GM has successfully integrated lifepo4 batteries into the large EV chassis typically designed for Ultium NCM pouch batteries, while still achieving a range of over 350 miles (approximately 563 kilometers).

To better compete with Chinese battery manufacturers that dominate the global supply chain, GM plans to open a battery R&D center at its technical center in Warren, Michigan by 2027. This initiative will help accelerate the development and innovation of battery technologies, boosting GM's competitiveness in the EV market.

It's important to note that GM is not abandoning the Ultium brand or its "one-size-fits-all" approach to battery systems. Instead, the company is flexibly adjusting its battery strategy based on market demand and technological trends. Kelty mentioned that GM will meet production demand by 2025 and has already resolved the battery production issues it faced by the end of 2023.

Moreover, GM is exploring the use of new prismatic cells and high-end cylindrical cells. According to Kelty, the new prismatic cells could reduce the number of modules in a battery pack by as much as 75%, thereby lowering production costs and improving manufacturing efficiency. High-end cylindrical cells, on the other hand, will be used for "performance" vehicles to meet consumer demand for high-performance EVs.

Recently, GM announced that it would phase out the Ultium battery brand to further expand the types of battery chemistries used in its EVs. Since launching the Ultium brand in 2020, GM has incorporated NCM battery technology into various models, including those from Chevrolet, Cadillac, and Hummer. However, the Ultium brand did not achieve the expected market success, prompting GM to adjust its battery strategy.

Compared to NCM batteries, lifepo4 batteries have lower production costs, better safety, and do not rely on expensive and scarce elements like cobalt. GM expects that by using lifepo4 batteries, the average battery cost in its EVs will drop to $60 per kWh (about 420 RMB) between 2023 and 2024 and further decrease by $30 per kWh (about 210 RMB) by 2025.

Notably, on September 25, SAIC-GM jointly launched a 6C ultra-fast charging lifepo4 battery with CATL, which is planned to be implemented in its newly upgraded 900V high-voltage battery architecture starting in 2025.

Earlier this year, in March, reports indicated that CATL was negotiating a technology licensing agreement with GM, aiming to jointly build an lifepo4 battery factory in North America. The planned factory's annual production capacity would not be less than that of the plant CATL and Ford are building together. Ford's battery plant is expected to have an annual capacity of 20 GWh, which can support over 400,000 EVs.

In recent years, lifepo4 batteries have gained increasing popularity among overseas automakers. Tesla, Volkswagen, BMW, Mercedes-Benz, Ford, Hyundai, Renault, Nissan, Toyota, Honda, and other international carmakers have either started or plan to expand the use of lifepo4 batteries. Tesla CEO Elon Musk has stated that in the future, two-thirds of Tesla cars will use lifepo4 batteries, while one-third may still rely on NCM batteries.

In China, the world's largest EV market, lifepo4 batteries now have twice the market share of NCM batteries. Data from the Power Battery Application Branch shows that in the first half of this year, China's installed capacity of power batteries reached 203.7 GWh. Of this, NCM batteries accounted for 71.1 GWh (34.9%), a year-on-year increase of 19.3%; while lifepo4 batteries accounted for 132.5 GWh (65.1%), up 32.8% year-on-year.

It's not just GM; the entire U.S. market is increasing its investment in lifepo4 battery production. According to data from Adamas Intelligence, lifepo4 batteries currently account for less than 20% of announced U.S. battery production capacity. However, the consultancy predicts that by the mid-2030s, the share of lifepo4 batteries in the U.S. will rise to nearly 30%.

- Next:Great Power in the UK! Great Power 2024 energy storage new products are in high demand among European customers.

- Previous:EVE Energy Showcases Innovation at Intersolar Summit Africa 2025

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

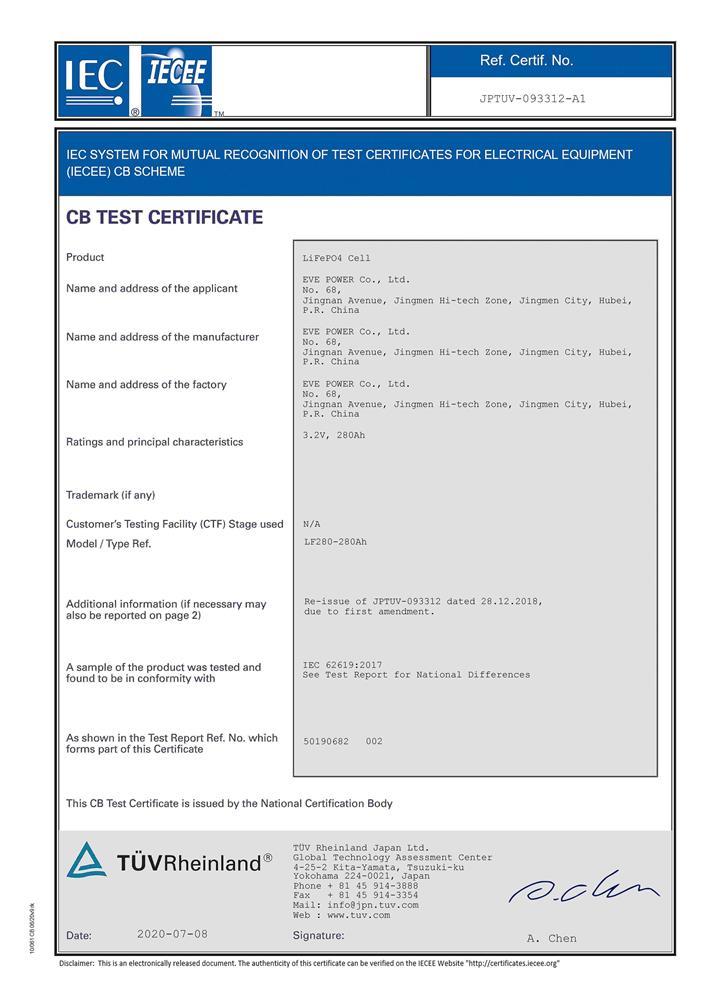

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia