News

CATL to Supply Large Cylindrical Batteries for BMW's "New Generation" Pure Electric Models Starting in 2026

At the 2024 BMW China Sustainability Supplier Day, CATL announced that starting in 2026, it will gradually supply large cylindrical batteries for BMW's "New Generation" pure electric models globally and in China.

According to BMW's product plan, the first "New Generation" model will be produced in Shenyang in 2026, and it will be customized based on the needs of Chinese consumers. BMW emphasized its confidence in the strength and resilience of the Chinese supply chain in the face of a rapidly changing market and fierce competition, and it will continue to adhere to its "win-win" strategy.

In fact, this cooperation is based on the long-term agreement signed by both parties in September 2022.

According to the agreement at that time, starting in 2025, CATL will supply large cylindrical batteries for BMW Group's "New Generation" pure electric models. CATL will produce standard 46mm diameter cylindrical batteries at its battery factories in China and Europe, with an annual production capacity of 20 GWh per factory to meet BMW's demand for high-performance batteries.

It is worth noting that BMW plans to produce its first "New Generation" pure electric model in Shenyang in 2026, specially tailored for the Chinese market.

CATL's statement also indicates its firm commitment to large cylindrical batteries, with plans for mass production and installation in vehicles within the next two years. As the global leader in power batteries, this move injects confidence into the seemingly uncertain future of the large cylindrical battery industry.

What is the Progress of CATL's Large Cylindrical Batteries?

From the delivery time announced by CATL, the delay to 2026 also suggests that the progress of the large cylindrical battery industry is not as smooth as previously imagined.

Recently, Reuters reported that CATL Chairman Zeng Yuqun stated that Tesla CEO Elon Musk doesn't know how to make batteries and that Musk's bet on the 4680 cylindrical battery is "doomed to fail and will never succeed."

This judgment is not groundless. Since 2020, Tesla has faced numerous setbacks on its road to mass production of the 4680 large cylindrical battery.

Recently, Tesla achieved the production of its 100 millionth 4680 battery. However, in terms of technological progress, the 4680 batteries produced by Tesla are primarily using the dry electrode technology for the anode. To meet its performance targets, Tesla needs to use the dual dry electrode and full-tab technologies simultaneously.

It is reported that Tesla plans to update four dual-dry-process 4680 batteries by 2026. This indicates that the industrialization of dual-dry-process 4680 batteries will take more than a year, which aligns with the timeline announced by CATL.

Tesla's bet on the dry-process 4680 large cylindrical battery was originally aimed at improving production efficiency to drastically reduce manufacturing costs. Domestic battery companies generally believe that the combination of dual-dry-process electrodes and full-tab technology in large cylindrical batteries, with a ternary high-nickel and silicon-based anode material system, will be suitable for the high-end passenger car market.

Given the current global application prospects of China's low-cost lithium iron phosphate batteries, Tesla's self-developed 4680 large cylindrical batteries are unlikely to have a competitive advantage.

Additionally, it is reported that within Tesla, the compensation for the autonomous driving FSD team is much better than that of the battery team, indicating that Tesla's true focus remains on FSD development.

Therefore, for Tesla, collaborating with battery companies to mass-produce 4680 batteries may be the potential meaning behind Zeng Yuqun's statement.

So, what is the progress of CATL's large cylindrical batteries? Since the long-term agreement with BMW was signed in 2022, CATL has disclosed very little information about the 4680 battery.

According to previous reports, by 2023, CATL had successfully developed two models of large cylindrical batteries, the 4680 and 4695, which have significant advantages in terms of cycle life and energy density. CATL also plans to set up eight production lines with a total capacity of 12 GWh for large cylindrical batteries. Currently, the large cylindrical battery team has high priority within the company and reports directly to the leadership.

CATL has a cautious attitude towards the application of large cylindrical batteries, focusing on high-end models rather than economy models. This indicates that CATL's development strategy for large cylindrical batteries is targeted, aiming to leverage their advantages in the high-end market. At the same time, CATL is actively collaborating with domestic and international automakers to promote the technology and market application of large cylindrical batteries.

In terms of production capacity, CATL's overseas large cylindrical production line will be located in Hungary. On November 20, CATL's regional operations director, Jason Chen, stated that the new battery manufacturing plant in Hungary is expected to start production in the second half of 2025. It is anticipated that the production of 4680 batteries will gradually ramp up thereafter.

Mass Production and Vehicle Integration of Large Cylindrical Batteries "In Progress"

Currently, major global battery manufacturers have basically completed the layout for large cylindrical batteries. After years of technological accumulation, domestic and international companies have established a certain technical reserve and commercialization trend in the large cylindrical battery field.

Industry insiders believe that although large cylindrical batteries still face challenges in mass production, such as technological processes, as companies improve their processes and production lines, the yield rate is expected to continue to rise, and the market prospects are broad.

According to statistics, large cylindrical battery shipments grew rapidly in 2024. From January to September 2024, shipments of 40-series cylindrical batteries reached 55 million units, a year-on-year increase of 90%. Shipments of 32-series cylindrical batteries were 80 million units, a year-on-year increase of 14.29%, while shipments of other types such as 26-series, 46-series, 60-series, and 66-series cylindrical batteries reached 392 million units, a year-on-year increase of 70.4%.

From a target market perspective, large cylindrical batteries are mainly applied in electric vehicles, energy storage, two- and three-wheeled vehicles, electric tools, and outdoor power supplies. Additionally, the electric aviation sector has become a promising blue ocean market for large cylindrical batteries in the future.

In the electric vehicle market, the 32-series, 46-series, and 60-series cylindrical batteries saw rapid growth in 2024, and their penetration rate is expected to continue increasing.

It is reported that domestic battery manufacturers mostly use lithium iron phosphate systems, mainly supporting A0 and A00-level models from companies like JAC, Changan, Wuling, and Chery. These are mainly supplied by companies such as Guoxuan, EVE Energy, and Ningfu New Energy.

Among them, the 46-series batteries supplied to passenger cars are all provided by EVE Energy. EVE Energy has already taken the lead in China in achieving mass production and delivery of the 46-series large cylindrical batteries. As of October 28, the vehicles equipped with these batteries have traveled a maximum of 130,000 kilometers, and there have been no battery safety incidents in the 24,000 delivered vehicles. As production ramps up in 2025, the shipment volume is expected to continue to rise.

In terms of production capacity, according to incomplete statistics, more than 50 companies worldwide have laid out large cylindrical battery products and made capacity plans, with over 20 companies planning GWh-level capacities. Companies such as Tesla, EVE Energy, CATL, Panasonic, Samsung SDI, Envision Power, and BYD have planned capacities exceeding 30 GWh, with clear target customers.

Regarding the mass production timeline, 2025 and 2026 are the years when these companies are generally planning to begin large-scale production. The large cylindrical battery mass production will drive the upgrading and iteration demand for upstream and downstream materials, structural components, and equipment in the industrial chain. Several industrial chain supporting companies have already secured orders for 4680 battery components.

From this perspective, Chinese companies are likely to maintain a leading advantage in the commercialization process of the 46-series large cylindrical battery.

- Next:BYD FinDreams Battery Unveils the World's First CTB Construction Machinery Battery

- Previous:EVE Energy Showcases Innovation at Intersolar Summit Africa 2025

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

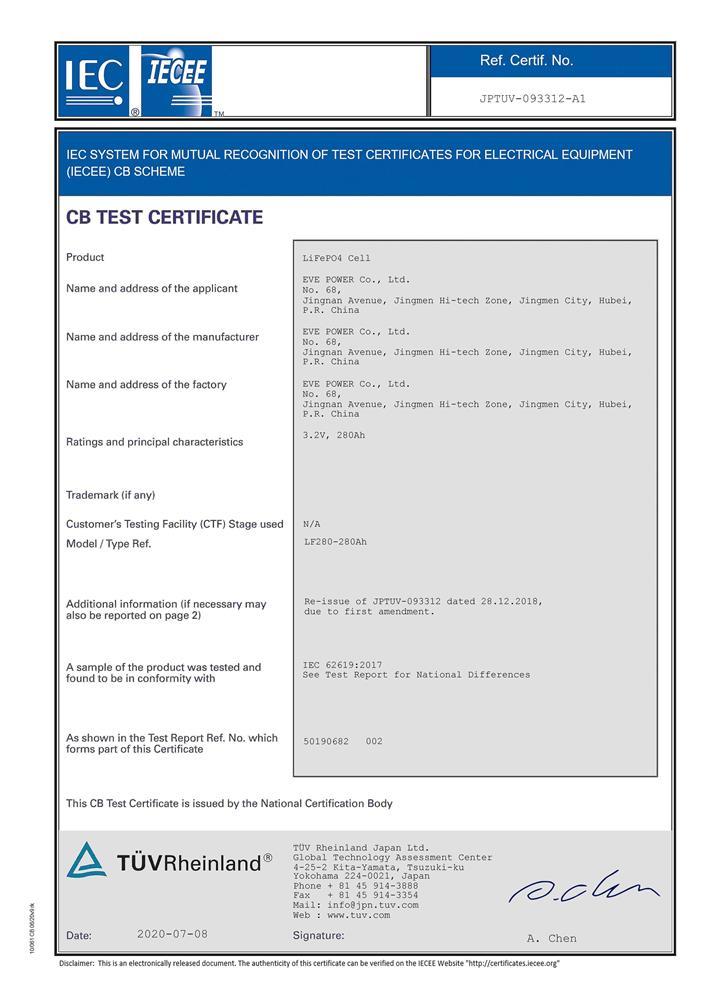

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia