Blog

Disrupting Tradition: Five Advantages of the 4680 Battery Leading the New Era of Electric Vehicles

In the lithium battery sector, the most well-known model is undoubtedly the 18650. This battery was initially widely used in consumer electronics and later expanded to electric tools. However, with the rapid development of the electric vehicle market, especially during the early days of Tesla, there was a lack of batteries specifically designed for electric vehicles, forcing Tesla to rely on the 18650 as a power source. While this choice addressed immediate needs, it also exposed the many limitations of the 18650 battery in electric vehicle applications.

In the passenger car sector, the limitations of the 18650 battery in size, safety, and range have made it increasingly inadequate. Although the introduction of the 21700 battery improved the situation somewhat, it still cannot meet the growing market demand. For example, a pure electric vehicle equipped with a 75KWh battery requires approximately 7,000 18650 batteries and around 4,400 21700 batteries. As electric vehicles become more popular, there is an urgent need for a more suitable battery cell, and increasing the cell size has proven to be a simple yet effective solution. Thus, the 4680 battery emerged as the ideal choice. Next, we will explore the five advantages of the 4680 battery.

1. Improved Assembly Efficiency

The enlargement of the cylindrical design can enhance assembly efficiency, compensating for the low assembly efficiency of smaller cylindrical batteries. Currently, the assembly efficiency of mainstream cylindrical batteries (18650/21700) is approximately 87%, with system assembly around 65%. In contrast, square batteries achieve efficiencies of 89% and 70%, respectively, highlighting the lower assembly efficiency of cylindrical batteries. However, as the diameter of the cylindrical battery increases, this gap narrows. The increased diameter of the battery support plate and current collector reduces weight, and the decrease in the number of battery cells within the pack reduces the amount of structural components, thereby improving both energy density and assembly efficiency.

2. Enhanced Safety

From a safety perspective, the large cylindrical cell, combined with the full-tab design, can significantly address heat dissipation issues and effectively improve safety. The shorter electronic flow path in large cylindrical batteries is expected to significantly reduce heat generation. Additionally, the full-tab design increases the surface area for heat dissipation, enhancing thermal stability; it can effectively improve rate performance by reducing internal resistance and increasing electron flow speed, thus enhancing fast charging capabilities. The linear contact of large cylindrical cells means that if one cell experiences thermal runaway, the spread of the problem to other cells will be slow. Furthermore, the design allows for serpentine heat pipes within cylindrical batteries, whereas square batteries can only dissipate heat from the bottom, resulting in smaller heat dissipation areas compared to the larger areas in cylindrical designs, theoretically achieving zero thermal runaway.

3. Advantages of Standardization

From a standardization standpoint, the large cylindrical design is more favorable for battery manufacturers. Being a standardized product allows for cost reduction and efficiency improvements in production. The methods for using and assembling these batteries are the responsibility of the application side, which may present some challenges for traditional automotive manufacturers regarding BMS (Battery Management System) control. However, for new energy vehicle manufacturers like Tesla, this represents an advantage. The high degree of standardization of the 4680 battery allows it to be used as a "structural battery," adaptable for various vehicle designs and benefiting from integrated casting to reduce manufacturing costs and achieve "extreme" manufacturing. Additionally, the design, manufacturing, and recycling of large cylindrical batteries can be standardized, ensuring structural stability throughout their lifecycle, with zero stress between the batteries. The cylindrical battery maintains its structure consistently from start to finish.

4. Significant Economic Improvement

The 4680 battery is also more economical. The transition from the 21700 to the 4680 size results in a 448% increase in cell volume while only increasing surface area by 180%. This indicates that as the diameter of the cylindrical battery increases, the proportion of structural components to the total weight of the battery pack decreases, thus improving the energy density of large cylindrical batteries and lowering the production cost per Wh. Upgrading from the 21700 cylindrical battery to the 4680 large cylindrical battery can reduce unit production costs by 14%.

5. Advantages of the Honeycomb Structure

The close bonding of numerous cylindrical cells into a honeycomb structure provides excellent overall stiffness while ensuring ample power, making this configuration a preferred choice for high-end electric sedans. If a vehicle's battery pack uses small cylindrical batteries, the complexity of control increases due to the larger quantity required, placing higher demands on the BMS technology of automakers. Conversely, the large cylindrical design reduces the complexity of BMS control; for example, a 75KWh vehicle with 7,000 small cylindrical batteries can be managed much more easily with just 950 large cylindrical batteries.

In summary, the 4680 battery stands out in various aspects such as improved assembly efficiency, enhanced safety, higher standardization, economic benefits, and honeycomb structure advantages, making it a significant driving force in the development of the electric vehicle industry. These advantages not only meet the urgent market demand for high-performance batteries but also provide more possibilities for the design and manufacturing of future electric vehicles. With the continuous advancement and widespread adoption of 4680 battery technology, it will play a crucial role in the future of sustainable transportation, facilitating broader applications and development of electric vehicles.

- Next:What is a LiFePO4 Battery?

- Previous:How to Tell if Your Lithium Battery is Safe? 7 Warning Signs You Should Know

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

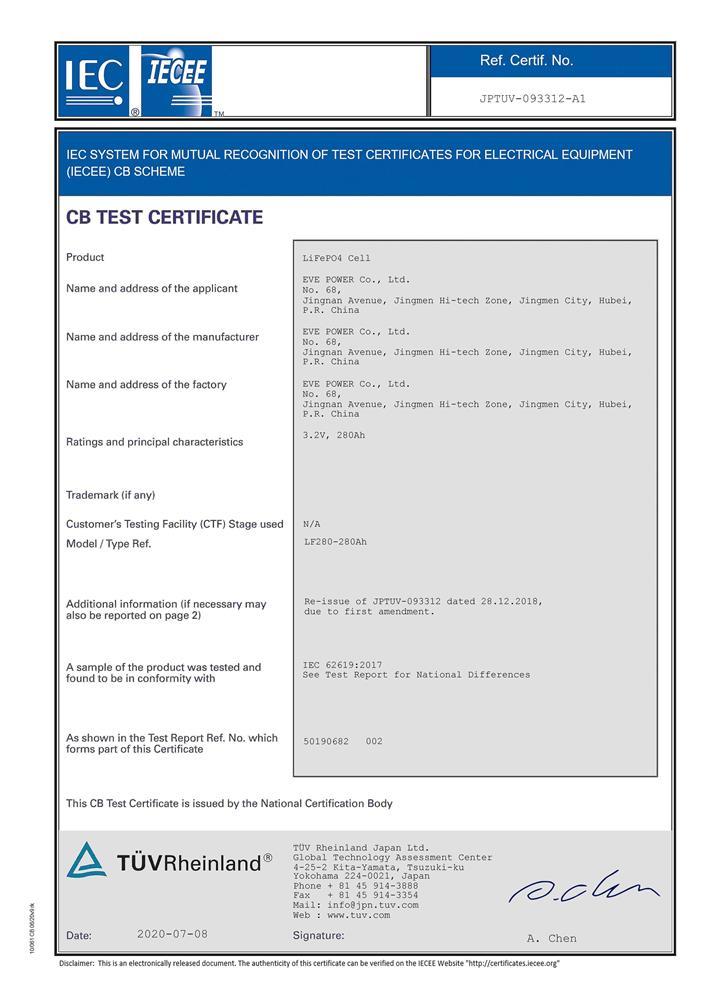

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia