Blog

Differences Between LiFePO4 Batteries and Ternary Lithium Batteries

Batteries come in many different types, typically categorized as chemical, physical, or biological. In terms of structure, they are divided into conventional batteries and fuel cells. For electric vehicles, the batteries in use today are primarily chemical batteries, including lead-acid, lithium titanate, lithium cobalt oxide, LiFePO4 (LFP), nickel-cobalt-manganese (NCM), and nickel-cobalt-aluminum. Among these, LFP and NCM batteries stand out for their higher energy density and stable performance, making them the most commonly used types in the electric vehicle market.

Since LFP and NCM lithium batteries are the most prevalent on the market, let's take a closer look at the differences between them.

Energy Density: NCM > LFP

Energy density is one of the key factors in evaluating battery performance. Simply put, the higher the energy density, the more charge a battery can store per unit of weight or volume, which translates to a longer driving range. For example, two stones of the same weight and size—one containing more impurities and the other less—will have different values depending on their extraction efficiency. In the same way, a higher energy density means a stronger ability to store power for the same volume.

LFP batteries, due to their inherent chemical properties, have a lower energy density of around 140Wh/kg. In contrast, NCM batteries, with a higher voltage, typically have an energy density around 240Wh/kg. This means that, for the same weight, NCM batteries offer roughly 1.7 times the energy density of LFP batteries.

Currently, NCM batteries are categorized into NCM523, NCM622, and NCM811 types. These names reflect the ratio of nickel, cobalt, and manganese used in the cathode material. For example, the NCM811 battery consists of 80% nickel, 10% cobalt, and 10% manganese—this "8:1:1" ratio has become the focus in the quest to improve battery performance.

As the demand for higher energy density batteries grows, the NCM811 variant, which boasts higher nickel content, is seen as a key development direction. The increase in nickel improves the specific capacity of the cathode material, which in turn boosts energy density and storage capacity.

Safety: LFP > NCM

When it comes to safety, LFP batteries are far superior. This is due to their better thermal stability. The thermal peak of LFP batteries exceeds 350°C, and the chemical components begin to decompose at temperatures between 500°C and 600°C. However, LFP batteries perform poorly at low temperatures. For example, a 3500mAh LFP battery pack could be considered worn out after just 100 charge-discharge cycles in temperatures as low as -10°C.

In contrast, NCM batteries are less stable, with decomposition starting at around 200°C. Under high temperatures, the electrolyte can combust quickly, potentially triggering a chain reaction that could lead to fires. As a result, electric vehicles equipped with NCM batteries often require additional temperature management and battery management systems (BMS) to ensure safety. In high-temperature conditions, LFP batteries are generally considered safer.

Low-Temperature Performance: NCM > LFP

In colder climates, it's common for electric vehicles to experience reduced range in winter. LFP batteries have poorer low-temperature performance compared to NCM batteries. LFP's operational limit is -20°C, and its performance in cold weather is suboptimal. For instance, the capacity retention of an LFP battery is about 60-70% at 0°C, around 40-50% at -10°C, and drops to about 20-30% at -20°C. In contrast, NCM batteries can function at temperatures as low as -30°C, with better discharge efficiency in cold weather. In similar low-temperature conditions, the winter range reduction for NCM batteries is less than 15%, which is significantly higher than that of LFP batteries.

Battery Lifespan: LFP > NCM

Battery lifespan refers to the number of charge-discharge cycles before the battery's capacity significantly degrades. Typically, a battery needs to be replaced once its charge drops below 80% of its original capacity. This is similar to the replacement standard for mobile phones.

Generally, LFP batteries can endure more than 3500 full charge-discharge cycles before reaching a point where their capacity drops below 80%. If an LFP battery is charged once per day, it could last for nearly 10 years before requiring replacement.

In contrast, NCM batteries have a shorter lifespan. After around 2000 cycles, their capacity starts to degrade, and their typical lifespan is around 6 years. However, with advanced battery management techniques, the lifespan of NCM batteries can be extended slightly, though the improvement is relatively modest.

Of course, the life of a battery pack is not simply the sum of the individual cell lifetimes. As a combination, if the performance of the batteries is highly consistent, the life of the battery pack can only approach the lifetime of a single battery.

Manufacturing Costs: NCM > LFP

When it comes to manufacturing costs, LFP batteries have a clear advantage. LFP does not contain expensive metals like nickel and cobalt, which makes the production process less costly. On the other hand, NCM batteries require a mix of nickel, cobalt, and manganese, and the production of high-nickel batteries requires more stringent conditions, leading to higher costs.

Furthermore, the prices of lithium and cobalt, essential materials for these batteries, have been rising due to resource shortages. The cost of cobalt, for example, has surged to over 200,000 RMB per ton, while electrolytic nickel costs about 110,000 RMB per ton. As a result, many battery manufacturers are turning to NCM811, which increases nickel content and reduces cobalt content to lower production costs.

Conclusion

When comparing LFP and NCM batteries, it's clear that both have their own strengths depending on factors like energy density, safety, low-temperature performance, lifespan, and cost. These differences have led to divergent pathways in the development of lithium battery technologies.

- Next:How long does it take to charge a 48v lithium ion battery?

- Previous:How to Tell if Your Lithium Battery is Safe? 7 Warning Signs You Should Know

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

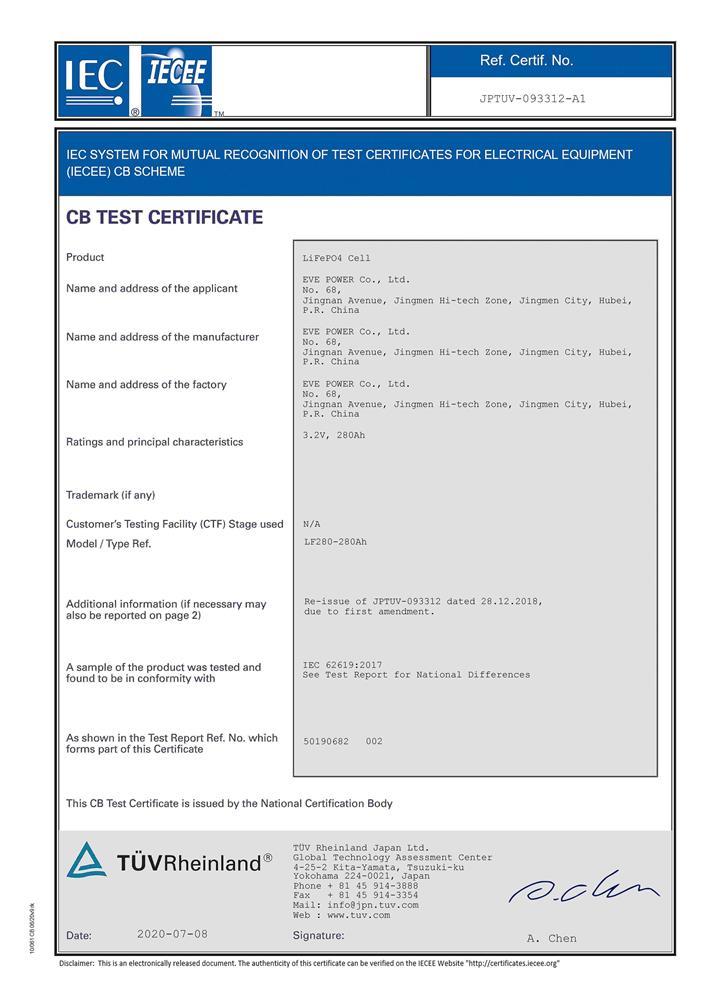

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia