Blog

Comparison and Analysis of Cylindrical, Prismatic, and Pouch Lithium Batteries

Currently, there are three main packaging types for lithium-ion batteries: cylindrical, prismatic, and pouch. Each packaging type has its own set of characteristics, advantages, and disadvantages. Let's explore the features of these three types of batteries.

Cylindrical Lithium Batteries

Appearance: Cylindrical lithium batteries have a cylindrical shape, similar to individual battery cells. The positive and negative terminals are located at either end, and the casing is usually made of metal.

Manufacturing Process: The manufacturing process for cylindrical lithium batteries is highly developed, with a high degree of automation, leading to a high yield and relatively low production costs.

Performance Characteristics:

High Energy Density: Cylindrical batteries generally offer a higher energy density compared to other packaging formats.

Excellent Heat Dissipation: Due to the smaller size and larger surface area, cylindrical battery packs have better heat dissipation compared to prismatic batteries.

Consistent Quality: Cylindrical batteries are known for their good consistency, high thermal tolerance, and strong safety features, making them less prone to explosions.

Applications: Cylindrical lithium batteries are widely used in electric vehicles, power banks, drones, and other applications.

Advantages and Disadvantages:

Advantages: Compact size, high energy density, large capacity, mature manufacturing process, good consistency.

Disadvantages: Limited potential for increasing system energy density, high requirements for the Battery Management System (BMS), lower space utilization compared to prismatic batteries.

Prismatic Lithium Batteries

Appearance: Prismatic lithium batteries are typically rectangular or square, and their size and shape can be customized to meet specific requirements, offering greater flexibility.

Manufacturing Process: The manufacturing process for prismatic batteries is more complex, but the packaging reliability is high, leading to greater system energy efficiency.

Performance Characteristics:

High Energy Density: Prismatic batteries offer even greater potential for energy density improvements compared to cylindrical batteries.

Simple Structure: Prismatic batteries have a simple structure, making them easier to scale up in capacity, and they typically offer higher individual cell capacity.

Heat Dissipation Design: Heat dissipation is easier to design for prismatic batteries, and they can also be equipped with vent valves to enhance safety.

Applications: Prismatic lithium batteries are commonly used in portable devices such as smartphones, tablets, and digital cameras, where their thin design makes devices lighter and more portable.

Advantages and Disadvantages:

Advantages: High packaging reliability, high energy density, simple structure, easy to scale up capacity.

Disadvantages: Many different models, lower process uniformity, lower level of production automation, greater variation in individual cells, relatively lower yield and consistency.

Pouch Lithium Batteries (Polymer Lithium Batteries)

Appearance: Pouch lithium batteries have a thin, flexible appearance, with an aluminum-plastic film casing that offers enhanced flexibility.

Manufacturing Process: Pouch batteries require a more sophisticated manufacturing process, but their shape is highly customizable, allowing them to be made in almost any form to meet specific needs.

Performance Characteristics:

Good Safety Features: The aluminum-plastic film casing typically inflates and ruptures in the event of a safety issue, preventing explosions.

Lightweight: Pouch batteries are lighter compared to steel or aluminum-cased batteries. They also have lower internal resistance, reducing self-discharge rates.

Design Flexibility: The flexible form factor makes pouch batteries suitable for products with unique shapes, such as wearables and curved screens.

High Energy Density: Pouch batteries generally offer higher energy density than cylindrical or prismatic batteries.

Applications: Pouch batteries are increasingly popular in 3C digital products due to their high energy density and design flexibility.

Advantages and Disadvantages:

Advantages: Good safety features, lightweight, flexible design, high energy density.

Disadvantages: Lower consistency, higher cost, lower mechanical strength, and susceptibility to punctures from sharp objects.

Comparison of Cylindrical, Prismatic, and Pouch Lithium Batteries

| Category | Cylindrical Lithium Battery | Prismatic Lithium Battery | Pouch Lithium Battery |

|---|---|---|---|

| Production Yield | High | Relatively High | Average |

| Cell Consistency | High | Relatively High | Relatively High |

| Mechanical Strength | High | Relatively High | Average |

| Production Automation Level | High | Relatively High | Average |

| BMS Requirements | High | Average | Average |

| Battery Grouping Efficiency | Relatively High | High | Average |

| Shape Flexibility | Relatively High | Average | High |

| Application Areas | Electric vehicles, light electric vehicles, power tools, consumer electronics, new energy storage, etc. | Electric vehicles, light electric vehicles, new energy storage, etc. | Electric vehicles, consumer electronics, etc. |

| Major Battery Manufacturers | LG Chem, Panasonic, Samsung SDI, Lishen Battery, EVE Energy, BYD | CATL, BYD, Samsung SDI, Gotion | Farasis Energy, Wanxiang A123, GuoNeng Battery, Desay Battery |

| Future Technological Trends | Continuous improvement in battery performance and cost reduction; further automation and production efficiency improvements; new models for different applications, such as Tesla's 46800 large cylindrical battery. | Continuous improvement in battery performance and cost reduction; increased standardization and production automation; large storage applications gradually evolving toward module-free designs. | Continuous improvement in battery performance and cost reduction; increased production automation; large storage applications gradually evolving toward module-free designs. |

As lithium-ion battery technology continues to evolve, the choice between cylindrical, prismatic, and pouch lithium batteries depends on specific application requirements. Each design offers unique advantages, and careful consideration of factors such as space limitations, flexibility, weight, and cost will help determine the most suitable battery type for each particular use case.

- Next:How to Differentiate Between Grade A, B, and C LiFePO4 Cells?

- Previous:How to Tell if Your Lithium Battery is Safe? 7 Warning Signs You Should Know

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

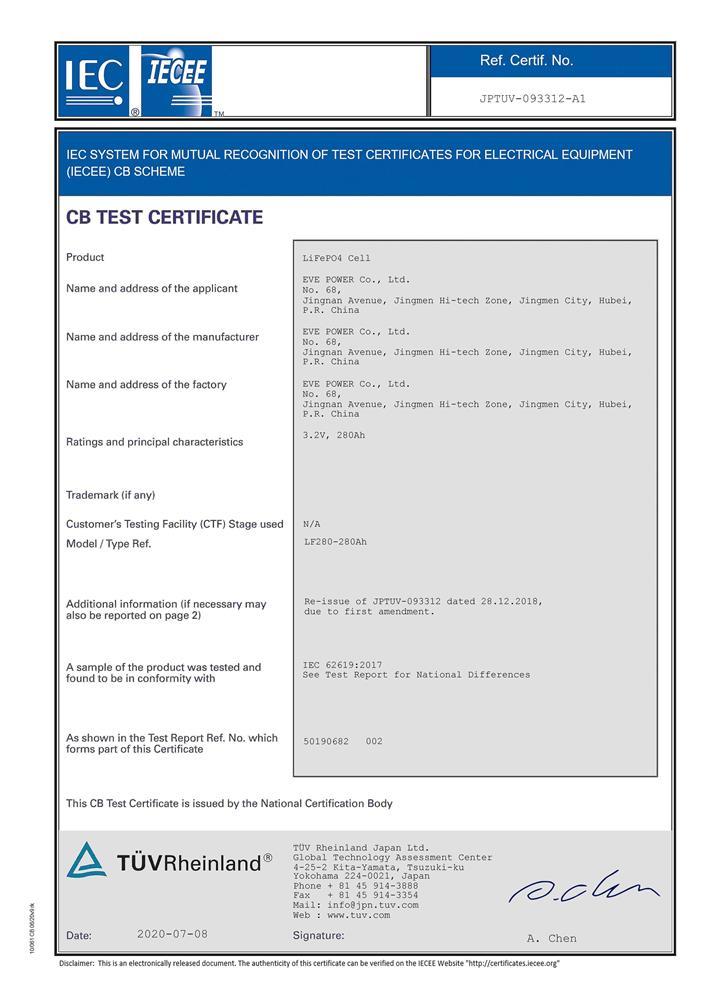

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia